“A new generation of students has access to 3D printers and other DIY technology…” |

I was speaking recently to one of our colleagues at Temple University about a project several of his students were working on, and he said something that really struck me, “these students are the first generation to have grown up with 3D printers in their schools, some even in their basements. They know how to use these and other maker tools, and it’s changing education,”

He’s right – every year now, we see more and more schools with Maker Spaces, 3D printers, DIY Electronics, and time set aside for creative, scientific projects. These students are already outpacing the old standards and this phenomenon certainly heralds a bright future!

The project we were discussing was a multi-channel neuroprosthetic that his students were developing with 3D modeling software, a 3D printer, and Backyard Brains tools! Check it out below:

A new trend? Students develop Neuroprosthetics, start Student Organization

This past summer, rising sophomore Morgan R., of Temple University pursued a summer project: with the help of one of her professors, she began the process of developing an affordable, 3D printed Neuroprosthetic powered by the Backyard Brains SpikerShield. What started as a fun summer project grew when she started bringing her friends and classmates on board. Thanks to their interdisciplinary connections, they realized they had the opportunity to make something out of the project and started a Neuroprosthetics Organization at the university, with the aim to develop and donate affordable prosthetics to those of different ability who could benefit from assistive technology.

Their work was made possible thanks to the Creative Arts, Research, and Scholarship (CARAS) program, a funding opportunity at Temple for undergraduates which supports undergraduate creative and scholarly projects.

We reached out directly to Morgan, and her classmate Gabby to learn more about the project, and after some Q&A they provided us with a lot of great details about their project! Below are their words and photos as they describe the process involved, from idea, to prototyping, to student org!

Morgan and Gabby: Our team launched this project by examining the question: How can we make prosthetics more accessible to the general public? After doing research on the industry and current methods, we concluded that they were so expensive because many of the companies who make them are mostly research and prototype oriented and not thinking about accessibility to end users who could use them today.

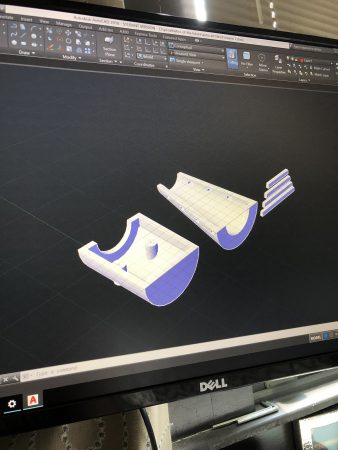

For our design, we concluded that a myoelectric (or EMG) prosthetic hand could be developed to be both affordable and versatile. We constructed the hand through an engineering program called AutoCAD. This software allows the user to create three-dimensional models that can be printed using a 3D Printer. We drafted two separate original designs for the hand and deliberated the pros and cons of both versions.

We decided upon our preferred design, then we printed and assembled our first hand.

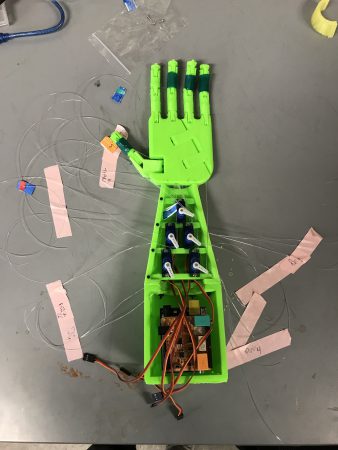

In the end, we decided to print the fingers in three separate pieces, the palm in two separate pieces, and a forearm structure. There were channels running through the palm into the fingers to allow strings of fishing line to run up the forearm structure and loop through at the tips of the finger digits. Each finger needed three strings, so there were about 15 strings total, so after the loop at the top there were about thirty strings running through the tunnel opening.

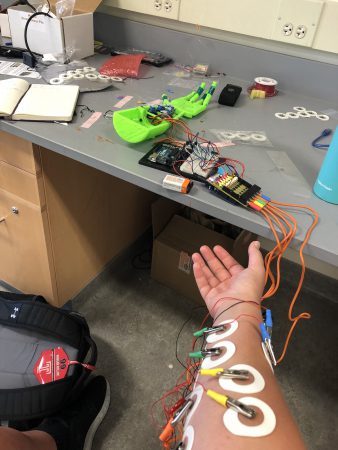

We came up with a strategy to organize the assortment of strings running through the bottom by two different color coding systems (one upon which finger it was and the other was whether the string received constant tension or an occasional burst. From there, we attached the strings from the opening of the tunnel to servos installed in the forearm attachment. The servos were then connected to an Arduino breadboard and the muscle backyard brains SpikerShield pro. We then used their code to experiment with the mechanism.

Results:

We are excited to continue moving forward with this project this project and to continue research in this field. During the next phase of the project, we would like to use a more precise 3D printer, to reduce the amount of variation from the 3D model to the print. Furthermore, we would like to find a better material to use instead of fishing line, as the degree of motion is not where we would like it to be. The fishing line could only handle so much tension, furthermore, the natural tendons found in the body have more elasticity than the fishing wire. We need to be able to apply a similar degree of tension to the line to create natural movements without the assistance of an external wire.

We also face issues on the software side. It is challenging to identify individual finger movements through EMG signals. We came up with a few short-term solutions for this: for example, with the single channel SpikerShield, we set finger servomotor activation at different thresholds, so depending on how strong the user’s flex was would change what fingers were activated. The 6-channel SpikerShield Pro has a lot of opportunities to offer individual finger control, but it is challenging to differentiate so many different signals from the forearm.

We are proud of what we’ve accomplished in such a short amount of time and see this as a strong foundation for our future work. We don’t doubt that we will be able to overcome these obstacles. We hope to have the prosthetic working well enough in the next year to give it to a living patient.

From an academic perspective, this project allowed us to put the skills that we gained through our engineering classes to practical use. Furthermore, it allowed us to experience working on a team with individuals who were not all pursuing the same field of study. Teamwork and reliability were key to the success of the project, it took the knowledge and skill of each discipline of the team to succeed.

—–

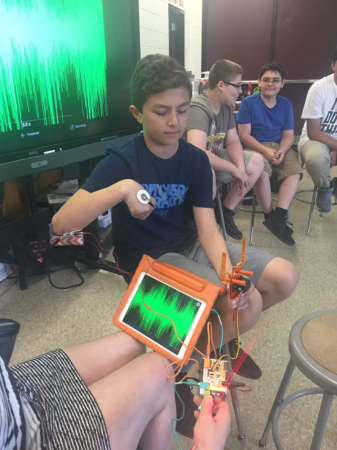

This team’s work is a great example of a growing trend: there is a new generation of students who have grown up with access to 3D printers, Arduinos, and other DIY tools. They are also one of the first student groups to begin with the single channel Muscle SpikerShield Bundle and then upgrade their design to allow for multi-channel control by implementing the Muscle SpikerShield Pro!

As you can see above, the students’ development involves a lot of trial and error as they work on functionally mimicking the movement of their prosthetics’ fingers. They are making great progress, and we are excited to share updates from them as their work continues over the school year!

Not just University Students…

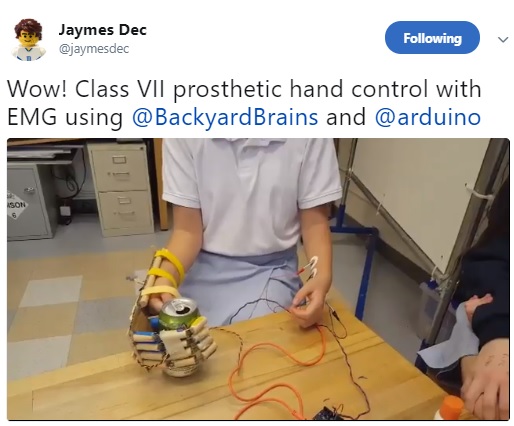

It’s not just university students developing Neuroprosthetics and assistive neuro technologies! Here are a few examples of MS and HS students who have developed their own devices using Backyard Brains kits.

This prosthetic grabber was made with a simple servo motor and is strong enough to grip and lift a can of sparkling mineral water! Now nothing will stop anyone from enjoying their bubbles.

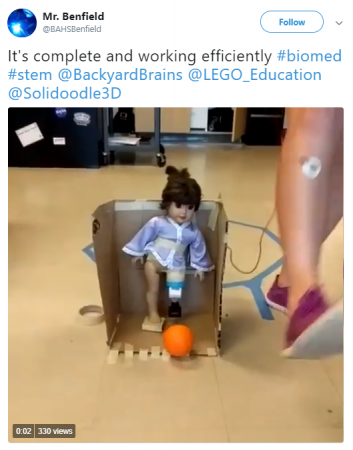

This is a great example of a functional prosthetic model, or Biomimicry – by combining our kits with Lego Mindstorms, the students created a doll that would mimic another students kick by recording from their leg.

This student combined his VEX robotics kit with a Muscle SpikerShield to create his NeuroClaw!

Planning an 8th Grade DIY Neuroprosthetics Lab

Ms. Farkas has big plans for her 8th graders this year: continuing their experience with DIY neuroscience from last year, she is branching into the world of prosthetics! Following a successful Donors Choose, she is now planning a unit where groups of students will all be responsible to design and create devices which will be controlled by their nervous systems!

She describes it best:

My Project

This year, we want to continue my students’ Neuroscience journey! With the help of the Backyard Brains Muscle SpikerShield Kits, we plan to conceptualize, research, design, build and control our own Neuroprosthetics. Through collaboration with the team at Backyard Brains, we are piloting a project aimed at middle school students!

We’re excited to update you on the results of her class projects!

Required Kit:

Muscle SpikerShield / Pro

Develop your own Neuroprosthetics using the Arduino based Muscle SpikerShield or Muscle SpikerShield Pro!